|

|

|

Production Quality Management

System

Production Quality Management System :

Production Quality Management System :

It is all you need to

instantly establish Six Sigma production quality

monitoring system

-

Six Sigma process control

that utilize

-

DPU, Throughput Yield, Cycle Time, Sigma

Level

-

Pareto Analysis of

production defects

-

Corrective Action Request

Management

-

Process Knowledge Base

Management

Key Benefits:

Key Benefits:

|

|

Instantly establishing a Six Sigma process control

system

-

Following the built-in process

map and Traveler to collect basic production

data such Production Input, Defect Qty and etc.

-

System automatically

calculating the data and converting the data to

Six Sigma measurements e.g. Throughput Yield,

DPU, Sigma Level and etc.

-

No specific Black Belt or

Green Belt training is needed

Saving time and administrative support on your

everyday tasks

-

Entering data once and sharing

it seamlessly with users (network license

is needed)

-

Install-n- play. No special IT

support is needed

-

Built-in Pareto Analysis to

identify key issues

|

|

|

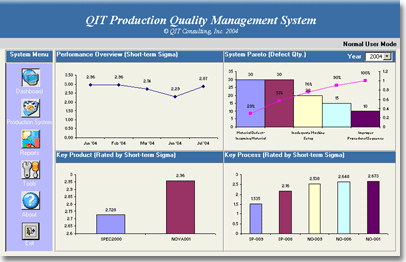

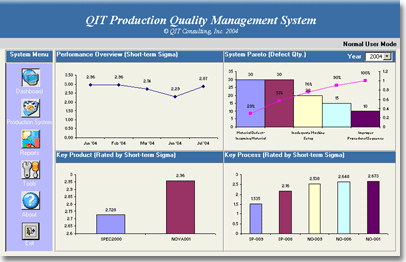

Getting a complete view of your production

performance through sophisticated reports with

auto-updated charts

Quantitative analysis -

use Six Sigma measurements such as Yield, DPU,

DPMO, Cycle Time, and Sigma Level, and

automatically updated charts to report process

performance

Qualitative analysis -

Use Pareto analysis and charts to identify key

process and product

Failure mode analysis - use

failure mode trending and charts to monitor the

long-term system, product, and process

performances, and the evaluate the effectiveness

of the improvement activities

Reports on work order,

process, product and system levels

|

|

|

|

|

Features at a Glance:

Features at a Glance:

|

-

A cost-effective Six Sigma

production quality management solution

-

Flexible and scalable

-

Capable of handling 1 to 250

LAN users or upgrade to MS SQL 2000/2005 for

better performance and reliability (network

license is needed)

-

No IT support required

-

Ideal for

- Manufacturing

- OEM Supplier

- Medical Device

- Household

Products

- Cosmetic

Products

|

-

Retaining process quality data

-

Converting process data to Six

Sigma measurements

-

Using Six Sigma measurements

e.g. Throughput Yield, Cycle Time, DPU, Sigma

Level to monitor process performance

-

Built-in Pareto analysis to

identify key issues

-

Fully integrated with QIT

Corrective Action Management System Desktop

Edition

-

Reporting process, product and

system performance

|

Testimonials

|

I have highly

recommended QITs software and services

to others within the corporation and

will continue to recommend QIT!

Marcella

|

|

|

|